Screw conveyor

- Category: Products

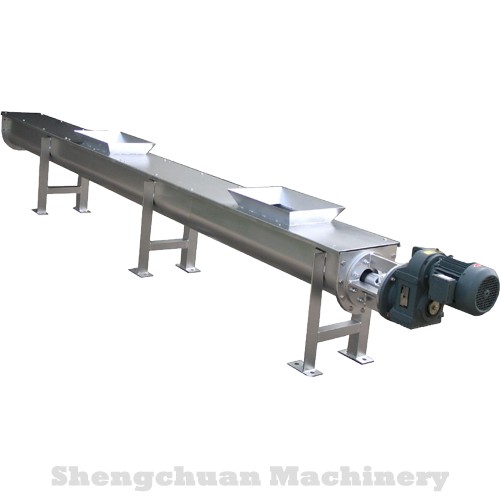

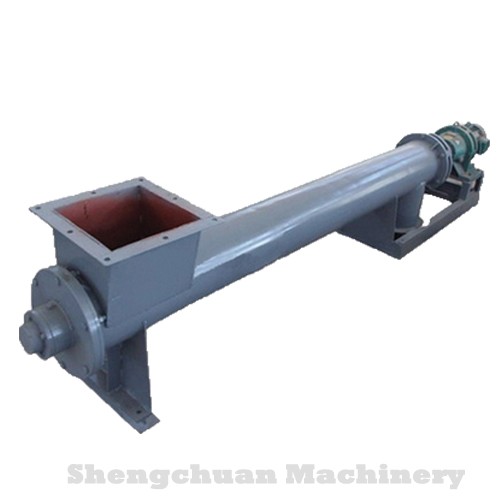

A screw conveyor is a machine that uses a motor to drive a screw to rotate and move materials to achieve conveying purposes. It can be transported horizontally, obliquely or vertically, and has the advantages of simple structure, small cross-sectional area, good sealing, convenient operation, easy maintenance, and easy enclosed transportation. Screw conveyors are divided into two types: shaftless screw conveyors and shaftless screw conveyors in terms of conveying forms, and are divided into U-shaped screw conveyors and tubular screw conveyors in terms of appearance. Shaft screw conveyors are suitable for non-sticky dry powder materials and small particulate materials. (for example: cement, fly ash, lime, grain, etc.) and shaftless screw conveyors are suitable for conveying viscous and easily entangled materials. (For example: sludge, biomass, garbage, etc.) The working principle of the screw conveyor is that the rotating screw blades push the material to be transported by the screw conveyor. The force that prevents the material from rotating with the screw conveyor blades is the weight of the material itself and the friction resistance of the screw conveyor shell to the material. For the spiral blades welded on the rotating shaft of the screw conveyor, the blade surface has solid face shape, belt face shape, blade face shape, etc. according to the different materials transported. The screw shaft of the screw conveyor has a thrust bearing at the end of the material movement direction to provide the axial reaction force to the screw with the material. When the length is long, a middle hanging bearing should be added.

Working principle:

When the screw shaft rotates, due to the gravity of the material and the friction generated by it with the wall of the tank body, the material can only move forward along the bottom of the tank body under the push of the blades. It is like a nut that cannot rotate along the rotating shaft. The screw makes a translational motion . The main forward power of the material comes from the force that pushes the material upward and forward in the tangential direction of the blade when the helical blade rotates axially. In order to keep the screw shaft in a favorable tension state, the driving device and the discharge port are generally placed at the same end of the conveyor, and the feed port is placed near the tail of the other end as much as possible. The rotating screw blades push the material to transport it. The force that prevents the material from rotating together with the screw conveyor blades is the weight of the material itself and the frictional resistance of the screw conveyor shell to the material. The face shape of the blade can be divided into solid face shape, belt face shape, blade face shape, etc. according to the different materials transported. The screw shaft of the screw conveyor has a thrust bearing at the end of the material movement direction to provide the axial reaction force to the screw with the material. When the length is long, a middle hanging bearing should be added.

performance characteristics :

1. The structure is relatively simple and the cost is low .

2. Reliable work and simple maintenance and management.

3. Compact size, small cross-section size, and small floor area. It is easy to enter and exit hatches and carriages during unloading and ship operations in the port.

4. It can achieve sealed transportation, which is conducive to transporting materials that are easy to fly, hot and have strong odors, reduce environmental pollution and improve the working conditions of port workers.

5. Easy loading and unloading. The horizontal screw conveyor can be loaded and unloaded at any point on its conveying line; the vertical screw conveyor can be equipped with a relative screw reclaimer to have excellent reclaimer performance.

6. It can be transported in reverse, or one conveyor can simultaneously transport materials in two directions, that is, toward the center or away from the center.

7. The unit energy consumption is large. 8. Materials are easy to be crushed and worn during transportation, and the wear of spiral blades and troughs is also serious.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Mr.Zhang

Mobile:+8615660875757

Tel:+8615660875757

Email:zhangshuai@jsflj.com

Add:No. 3, Blue Lane, Machinery Park, Zhonglian Machinery Manufacturing Base, Guhuang Road, Wen County Industrial Cluster, Jiaozuo City, Henan Province, China