Slat conveyor

- Category: Products

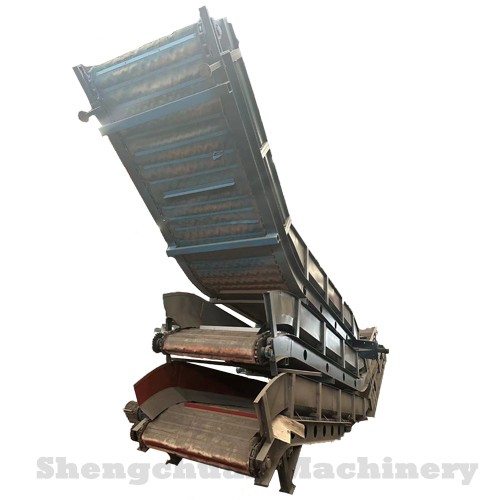

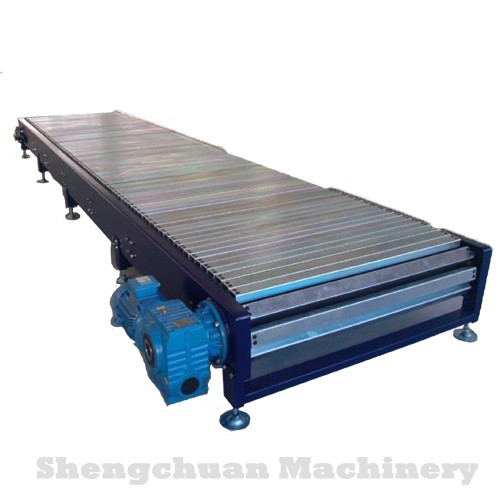

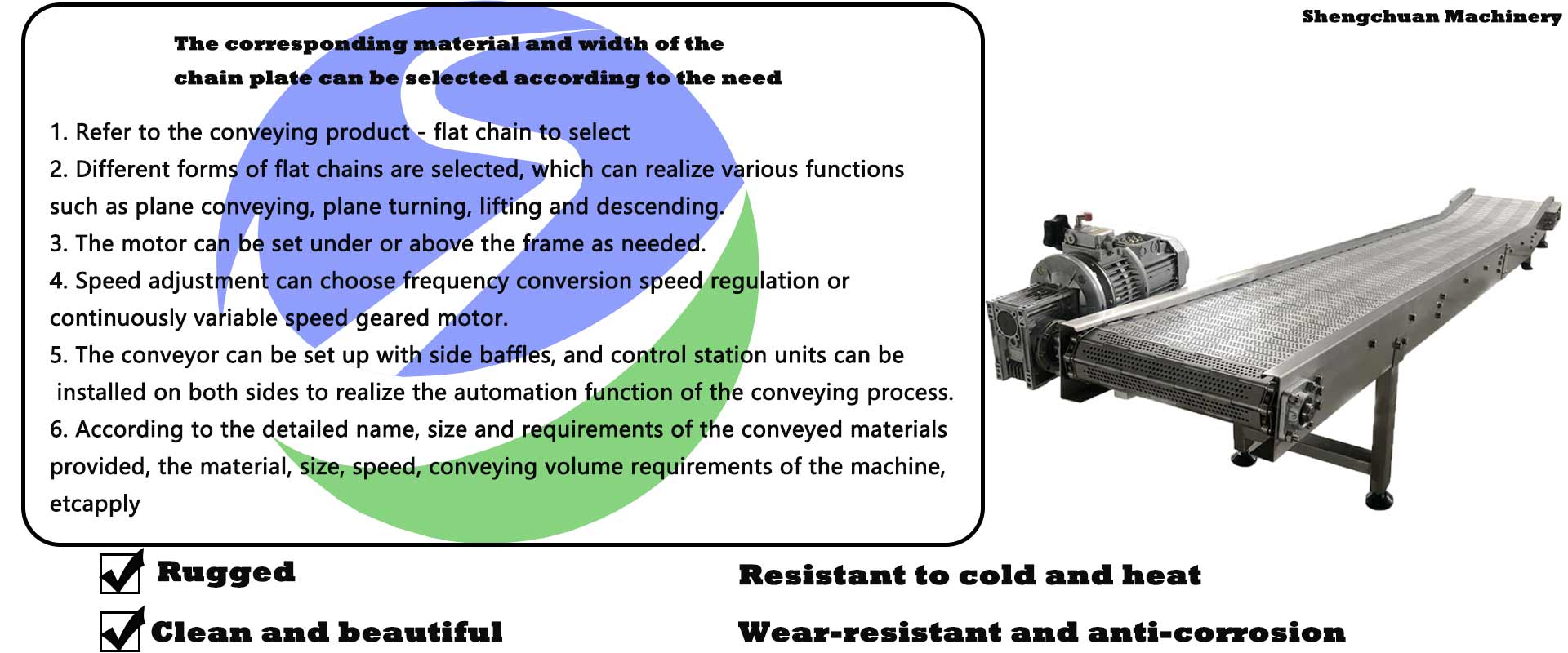

Chain plate conveyor is a conveying device that takes standard chain plates as the bearing surface and is driven by a motor reducer as the power. Chain plate conveyors consist of power units (motors), transmission shafts, rollers, tensioning devices, chain wheels, chains, bearings, lubricants, chain plates, etc. Among them, the two main parts that drive the transportation of materials are: the chain, which uses its circular reciprocating motion to provide traction power; and the metal plate, which serves as the carrier during the transportation process. Multiple rows of chain plates can be used in parallel to make the chain plate conveyor very wide and form a differential speed. The speed difference of the multiple rows of chain plates can be used to change the multiple rows of transportation into single rows of transportation without extrusion, thereby meeting the requirements of single row transportation of beverage labeling, filling, cleaning and other equipment. We can make the heads and tails of the two chain plate conveyors into overlapping mixed chains to keep the bottles (cans) in a dynamic excess state, so that no material is retained on the conveying line. It can meet the pressure and pressure-free transportation of empty and real bottles.

Working principle: Chain plate conveyors consist of power units (motors), transmission shafts, rollers, tensioning devices, chain wheels, chains, bearings, lubricants, chain plates, etc. Among them, the two main parts that drive the transportation of materials are: the chain, which uses its circular reciprocating motion to provide traction power; and the metal plate, which serves as the carrier during the transportation process. The main principle is to use a series of chains fixed to the traction chain to provide traction, and use metal plates as carriers to lead the material to be transported in the horizontal or oblique direction. Chain-plate conveyors are widely used in all walks of life, including power, metallurgy, brewing, chemical industry, medical care, machinery manufacturing and other broad fields. In order to meet the various needs of the production site, we can specifically design the conveying machines in the automation line to achieve the requirements and purposes.

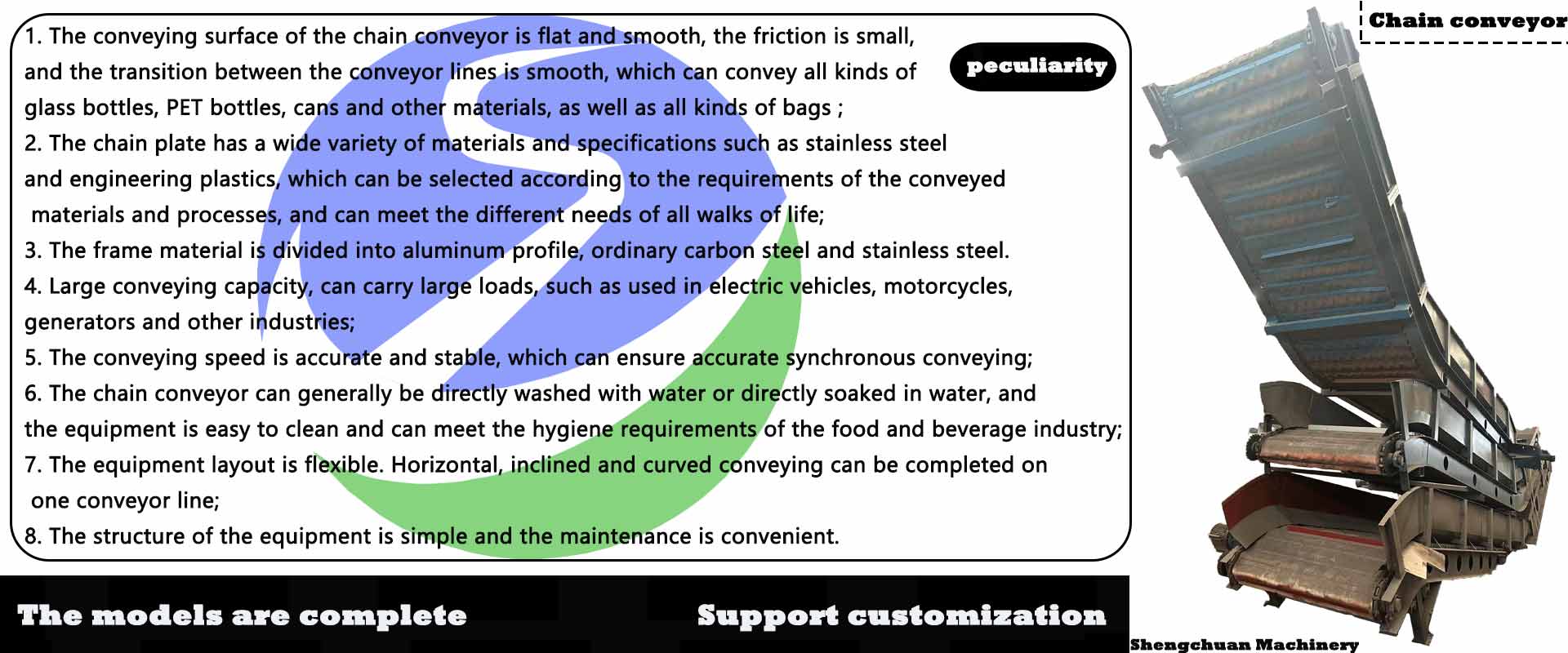

Features:

1. The conveying surface of the chain conveyor is flat and smooth, with small friction, and the transition of materials between the conveying lines is smooth. It can convey all kinds of glass bottles, PET bottles, cans and other materials, and can also convey all kinds of bags ;

2. Chain plates are available in stainless steel and engineering plastics and have a wide variety of specifications. They can be selected according to the transportation materials and process requirements to meet different needs of all walks of life;

3. The frame materials are divided into aluminum profiles, ordinary carbon steel, and stainless steel.

4. Large conveying capacity and can carry large loads, such as used in electric vehicles, motorcycles, generators and other industries;

5. The conveying speed is accurate and stable to ensure accurate synchronous conveying;

6. Chain plate conveyors can generally be directly washed with water or directly immersed in water. The equipment is clean and convenient, and can meet the hygiene requirements of the food and beverage industry;

7. Flexible equipment layout. Horizontal, inclined and turning transportation can be completed on one transportation line;

8. The equipment has simple structure and easy maintenance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Mr.Zhang

Mobile:+8615660875757

Tel:+8615660875757

Email:zhangshuai@jsflj.com

Add:No. 3, Blue Lane, Machinery Park, Zhonglian Machinery Manufacturing Base, Guhuang Road, Wen County Industrial Cluster, Jiaozuo City, Henan Province, China