Eddy current separator

- Product Item : 1000-

- Category: Products

It can also be popularized and applied in the field of environmental protection, especially in the non-ferrous metal recycling industry.

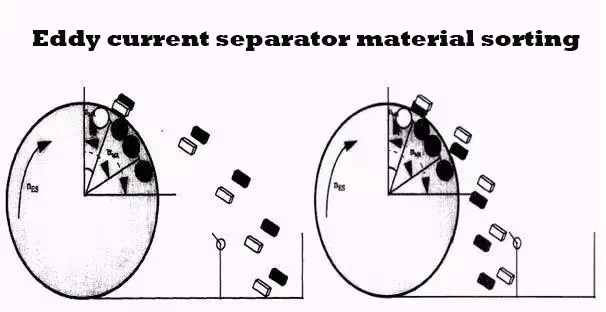

Eddy current separation is a separation technology that makes use of different electrical conductivity of materials. Its separation principle is based on two important physical phenomena: an alternating magnetic field that changes at any time is always accompanied by an alternating electric field (the law of electromagnetic induction); a current-carrying conductor produces a magnetic field.

When the electronic waste containing non-magnetic conductor metals (such as lead, copper, zinc, etc.) passes through an alternating magnetic field at a certain speed, the induced eddy current will occur in the gold scraps of these non-magnetic conductors.

Because there is a relative velocity between the material flow and the magnetic field, there is a thrust to the metal sheet and block that produce eddy current.

By using this principle, some non-ferrous metals can be separated from the mixture flow.

The thrust acting on the metal depends on the size, shape and degree of irregularity of the metal piece.

The direction of the separation thrust is 90 degrees with the direction of the magnetic field and the direction of the material flow.

How it works:

The non-ferrous metal separator is designed based on the principle that the conductor can produce induced current.

When the machine is working, when the metal enters the division area, it will induce an electric current inside the metal. The magnetic field generated by this current is opposite to the direction of the original magnetic field, and there is a mutually exclusive force. This repulsive force can throw the metal block forward to achieve the purpose of separation.

Product features:

1. Easy to operate, automatic separation of non-ferrous metals and non-metals, reduce labor, efficient recovery of non-ferrous metals, effectively increase output value.

2. It is easy to install and can be effectively connected with new and existing assembly lines.

3. The best sorting effect can be achieved by simple and flexible adjustment.

4. The equipment has the advantages of low energy consumption, high capacity and low cost.

5. Separation belts and rollers with different widths can be used to separate materials with different particle sizes.

6. The production cost is low and there is no environmental pollution.

7. The speed of precision magnetic drum and belt are stepless speed regulation, which can be adjusted more accurately and improve the sorting rate.

8. According to the needs of different working environment, we can design and produce concentric precision magnetic drum or eccentric precision magnetic drum.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Mr.Zhang

Mobile:+8615660875757

Tel:+8615660875757

Email:zhangshuai@jsflj.com

Add:No. 3, Blue Lane, Machinery Park, Zhonglian Machinery Manufacturing Base, Guhuang Road, Wen County Industrial Cluster, Jiaozuo City, Henan Province, China