Belt conveyor

- Category: Products

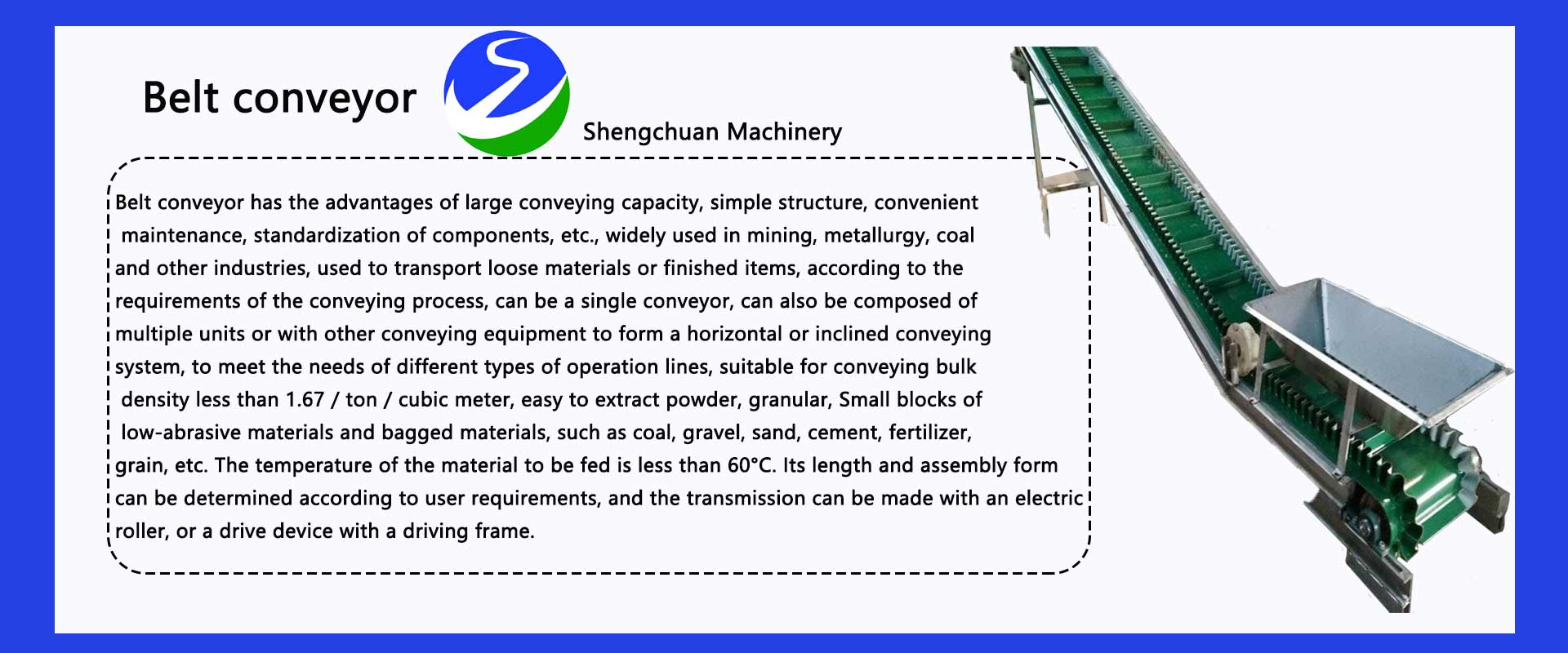

Belt conveyors have the advantages of large conveying capacity, simple structure, convenient maintenance, and standardized parts. They are widely used in mining, metallurgy, coal and other industries. They are used to convey loose materials or pieces of articles. According to the requirements of the conveying process, they can be transported by a single machine., or they can be composed of multiple machines or combined with other conveying equipment to form a horizontal or inclined conveying system to meet the needs of different arrangement types of operation lines. They are suitable for transporting bulk densities less than 1.67/ton/cubic meter. Powdered, granular, and small blocks of low-abrasive materials and bagged materials that are easy to extract, such as coal, gravel, sand, cement, chemical fertilizers, grains, etc. The temperature of the delivered material is less than 60℃. The captain and assembly form can be determined according to user requirements. The transmission can be made of electric rollers or a driving device with a driving frame.

Belt conveyors have various structures, including grooved belt conveyors, flat belt conveyors, climbing belt conveyors, side tilting belt conveyors, turning belt conveyors and other forms. Commonly used belt conveyors can be divided into: ordinary canvas-core belt conveyors, steel rope core high-strength belt conveyors, fully explosion-proof downward belt conveyors, flame-resistant belt conveyors, dual-speed dual-transport belt conveyors, reversible mobile belt conveyors, cold-resistant belt conveyors, etc. Belt conveyor is mainly composed of frame, conveying belt, belt rollers, tensioning device, transmission device, etc.

introduction of the principle:

Belt conveyors are widely used in home appliances, electronics, electrical appliances, machinery, tobacco, injection molding, post and telecommunications, printing, food and other industries, for assembly, testing, debugging, packaging and transportation of objects. Line transportation can be selected according to process requirements: general continuous operation, rhythmic operation, variable speed operation and other control methods; line bodies can be selected according to local conditions: straight lines, corners, slopes and other line forms.

Belt conveyors, also known as belt conveyors or belt conveyors, are indispensable economical logistics transportation equipment for forming a rhythmic assembly line. Belt conveyors can be divided into heavy belt conveyors such as mining belt conveyors based on their conveying capacity, and light belt conveyors such as those used in electronic plastics, food light industry, chemical and pharmaceutical industries. Belt conveyors have strong conveying capacity, long conveying distance, simple structure and easy maintenance, and can easily implement programmed control and automated operations. The continuous or intermittent movement of the conveyor belt is used to convey items below 100KG or powder and granular items. It runs at high speed, smoothly, has low noise, and can be transported up and down slopes.

Due to the advantages of large conveying capacity, simple structure, convenient maintenance, low cost, and strong versatility, TD75 and DTII belt conveyors are widely used in metallurgy, mining, coal, ports, transportation, hydropower, chemical and other departments to load, ship, transfer or accumulate various bulk materials or pieces with loose densities of 500 to 2500kg/m3 at normal temperature. Materials are transported by a single machine or a multi-unit synthetic transportation system, which can be arranged in a horizontal or inclined form according to process requirements. In addition to meeting the horizontal or inclined transportation requirements, the DTII belt conveyor can also adopt a combination of convex arc segments, concave arc segments and straight segments. The block size of material allowed by the conveyor depends on the bandwidth, belt speed, groove angle and inclination angle, and also depends on the frequency of large material appearance. The applicable working environment temperature of this conveyor is generally-25 ~+40℃. There are also light belt conveyors and mobile conveyors.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Mr.Zhang

Mobile:+8615660875757

Tel:+8615660875757

Email:zhangshuai@jsflj.com

Add:No. 3, Blue Lane, Machinery Park, Zhonglian Machinery Manufacturing Base, Guhuang Road, Wen County Industrial Cluster, Jiaozuo City, Henan Province, China