Radiator disassembly line

- Category: Products

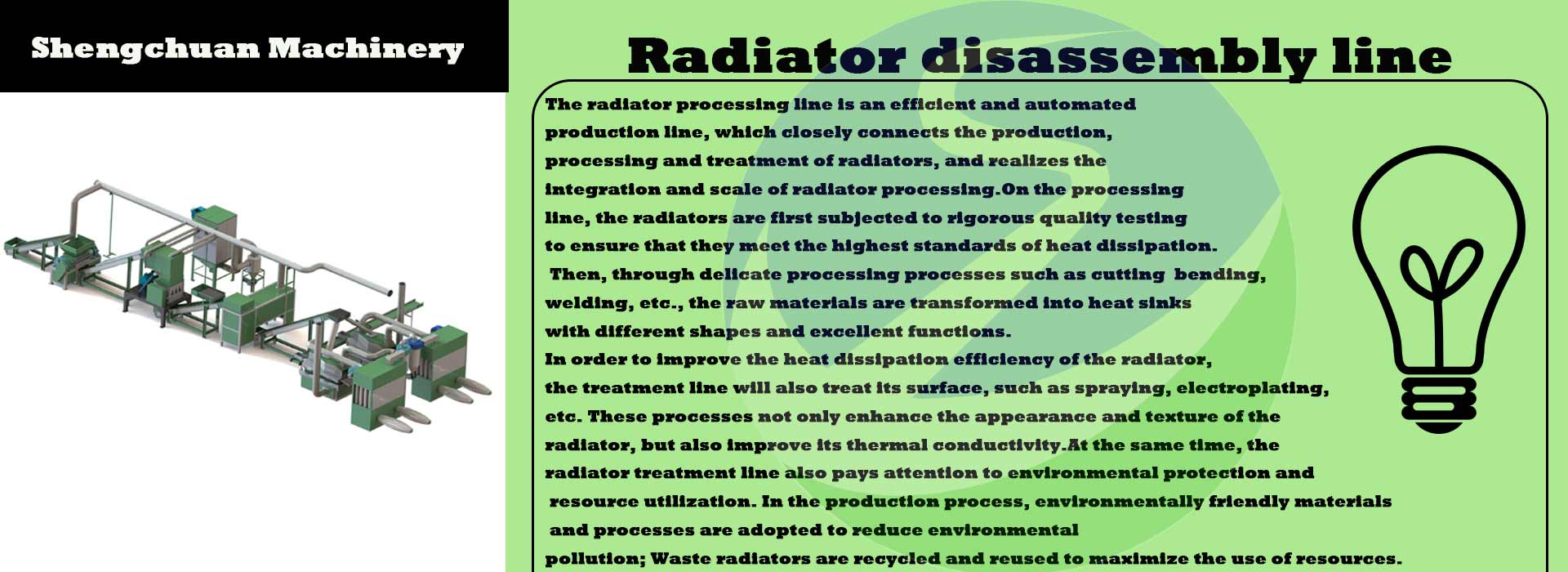

Radiators and water tanks are necessary for air conditioning and are indispensable in life and production today and in the future. The increasing development of these industries is driving the continuous innovation of waste radiator recycling technology. So far, the use of radiators and copper-aluminum water tanks in the market has gradually accelerated, and the recycling and reuse of used air conditioner radiator coolers and condenser water tanks is needed by the entire market environment.

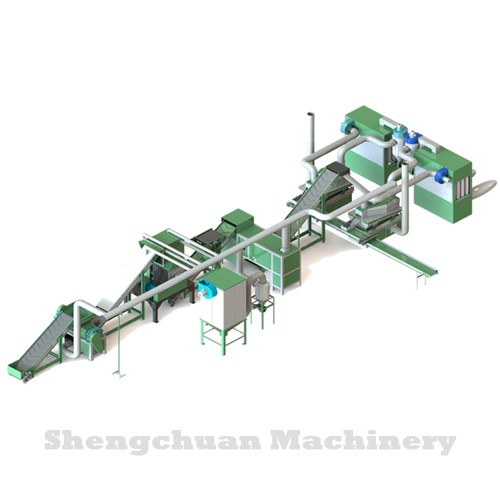

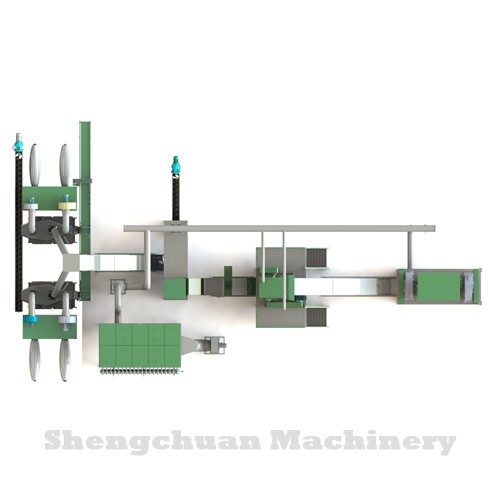

The copper and aluminum radiator dismantling machine is a strip-off radiator recycling machine that directly separates the copper tube from the aluminum cover. The copper-aluminum radiator separator is an integrated design with a small footprint and is suitable for small recycling factories.

Copper and aluminum water tanks originate from the fine dismantling of air conditioners and automobile water tanks. Their main components are copper pipes and aluminum foil waste. With the change of car scrapping and indoor air conditioning, a large number of waste copper and aluminum radiators came into being. These used copper and aluminum water tanks are regarded as valuable raw materials in the resource recycling market and have long attracted the attention of investors. However, faced with the high cost and low efficiency problems of traditional manual dismantling, automated dismantling technology came into being, bringing innovation to the copper and aluminum water tank dismantling industry.

Radiator copper and aluminum separation equipment has unique advantages in its automated dismantling process:

1. Highly automated, it can accurately separate aluminum and copper pipes in air conditioners, refrigerator radiators and copper-aluminum water tanks;

2. Operate efficiently and significantly reduce labor costs. The equipment adopts a double-door design, making maintenance and disassembly more convenient;

3. Adopt advanced PLC automatic control system to ensure collaborative work among various equipment and create a stable and reliable working environment;

4. The two-shaft double-roller shredder equipped at the front end of the copper-aluminum water tank crusher has low noise, high torque and a spacious crushing chamber, providing strong support for the dismantling work.

5. The equipment is equipped with advanced magnetic separation technology and uses a strong magnetic drum separator to accurately remove non-ferrous metals and iron impurities in the material to ensure purity.

6. Based on the precise gravity sorting principle, we use a high-efficiency airflow separator with a separation efficiency of up to 98%, providing you with excellent material purity.

7. Our mechanical equipment is simple and clear in design and reasonable in layout to ensure stable operation and bring you a worry-free experience.

Compared with traditional manual dismantling, our equipment has achieved a qualitative leap in processing speed, sorting efficiency and automation, and the loss rate is extremely low, only 2-3%. At the same time, using our equipment can significantly reduce processing costs, which is more than half lower than manual dismantling costs. This efficient and stable mechanical separation equipment is no longer subject to manual restrictions, has higher profit margins, and has attracted the favor of many investors.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Mr.Zhang

Mobile:+8615660875757

Tel:+8615660875757

Email:zhangshuai@jsflj.com

Add:No. 3, Blue Lane, Machinery Park, Zhonglian Machinery Manufacturing Base, Guhuang Road, Wen County Industrial Cluster, Jiaozuo City, Henan Province, China