Metal crusher

- Category: Products

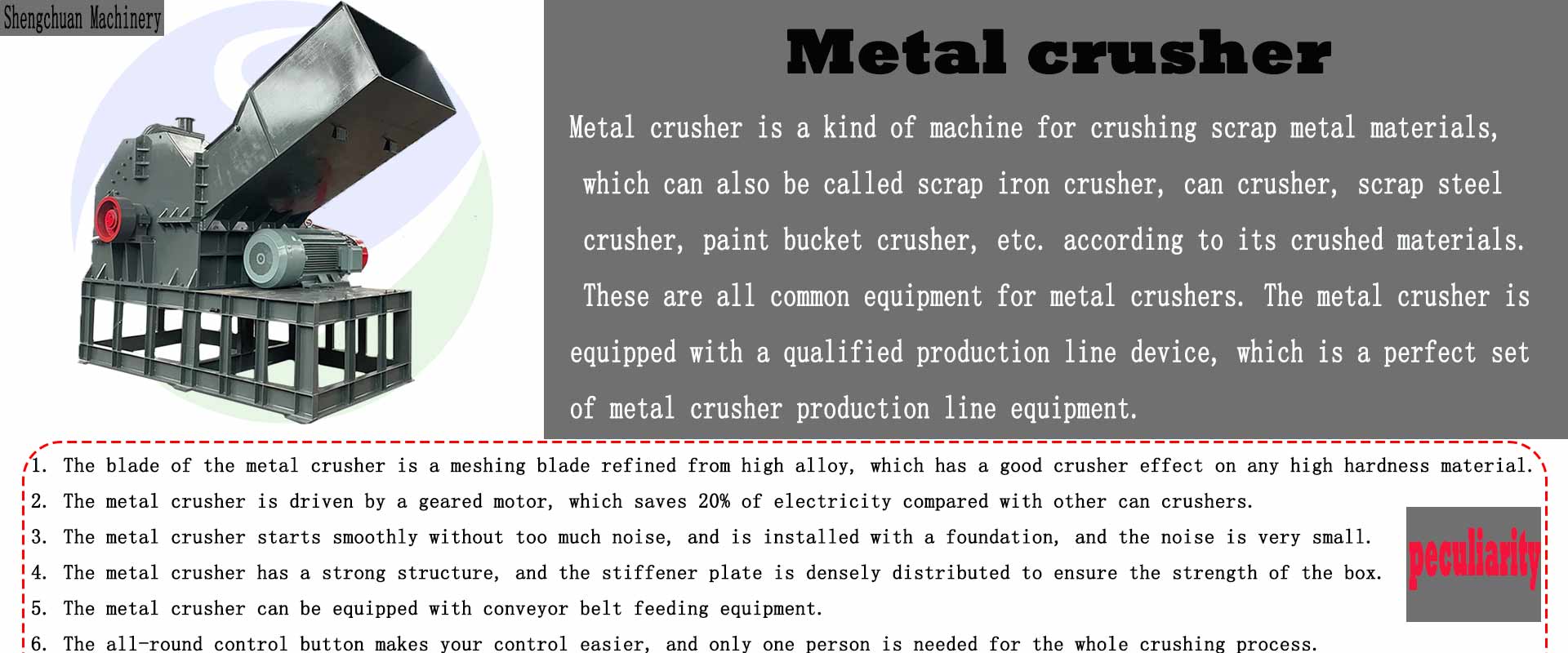

Metal crushers, also called metal crushers, are machines that crush scrap metal materials. Depending on the different crushed materials, they can also be called scrap iron crushers, can crushers, paint barrel crushers, etc. These are general equipment for metal crushers. Configuring the metal crusher with qualified production line equipment will provide a perfect set of metal crusher production line equipment.

Performance characteristics:

1. The blade of the metal crusher is a meshing blade refined from high alloy, which has a good crushing effect on any high-hardness material.

2. The metal crusher is driven by a reduction motor, which saves 20% electricity compared to other can crushers.

3. The metal crusher starts smoothly without too much noise, and is installed with a foundation, so the noise is very small.

4. The metal crusher has a strong structure and densely covered stiffening plates to ensure the strength of the box.

5. The metal crusher can be equipped with conveyor belt feeding equipment. 6. All-round control buttons make it easier for you to control, and only one person is needed for the entire crushing process.

Working principle:

The basic principle of a metal crusher using a motor to drive a wind wheel for extrusion is the basic principle of using a hammer to hit. The feeding port is equipped with a filter conveyor belt. Driven by a high-speed and high-torque motor, the hammer heads on the rotor of the main machine take turns. Hit the objects to be crushed entering the cavity, and tear the objects to be crushed into crushed objects that meet the specifications through the space formed between the lining plate and the hammer head. Metal crushers can be divided into dry systems, wet systems and semi-wet systems according to the working conditions of the crusher. The dry system mainly means that the broken materials must pass through the air swirling sorting system to separate metals and non-metals. In addition, the entire system is equipped with a dust removal device. The wet system refers to spraying water while crushing, and washing with water while sorting. These advantages of metal crushers can meet some basic requirements of electric furnace steelmaking for refined steelmaking and shortening smelting time to the greatest extent; and pure crushed steel can also be used as an additive for converter steelmaking. Broken materials pass through an air swirling sorting system to separate metals and non-metals. In addition, the entire system is equipped with a dust removal device to minimize the hazard of dust pollution generated during the production process. This equipment mainly has the advantages of high output, low energy consumption, high efficiency, and uniform discharge of materials. And when using the equipment, it has low noise, no pollution, simple operation and convenient maintenance. precautions.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Mr.Zhang

Mobile:+8615660875757

Tel:+8615660875757

Email:zhangshuai@jsflj.com

Add:No. 3, Blue Lane, Machinery Park, Zhonglian Machinery Manufacturing Base, Guhuang Road, Wen County Industrial Cluster, Jiaozuo City, Henan Province, China